"For us, accuracy and system uptime are just as critical as speed. Having reliable, AI-based vision in the process reduces manual intervention and gives us confidence in daily operations."

The Blind Spot in Modern Warehouses

You've automated everything except knowing what's actually happening in your warehouse.

Modern warehouses run on data, but lose visibility at critical moments. Between scans, items get miscounted, damaged, or misplaced. Your WMS makes decisions on assumptions, not facts.

- •

WMS says 10 items, reality is 9, orders fall.

- •

Damage happens between scans, discovered too late to fix.

- •

Misplacements go unnoticed, stock counted in the wrong location.

- •

Returns require manual inspection, hours of labour wasted.

- •

Wrong items reach customers, brand takes the hit.

Lens becomes your warehouse's intelligence layer. A continuous stream of validated data that turns your existing cameras into

How Lens creates warehouse intelligence

Beyond vision: A decision engine for your operations

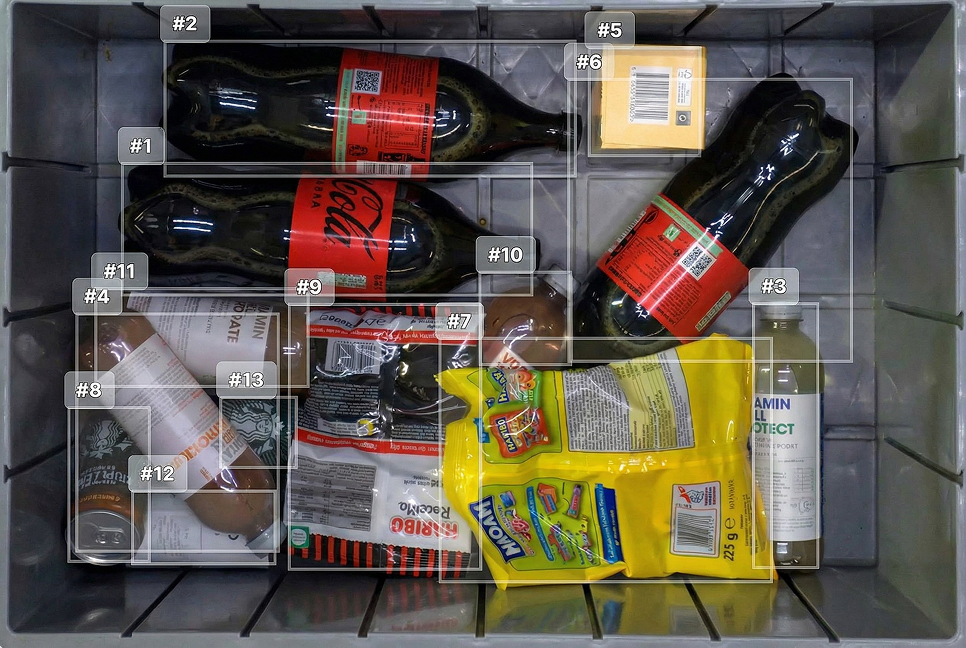

Lens isn't just computer vision - it's a complete intelligence platform that sits between your physical operations and digital systems. Lens runs on multi-modal vision models built from millions of real warehouse picks. It reads what's in every bin and feeds validated data into your systems so operations act on facts instead of assumptions.

The intelligence pipeline

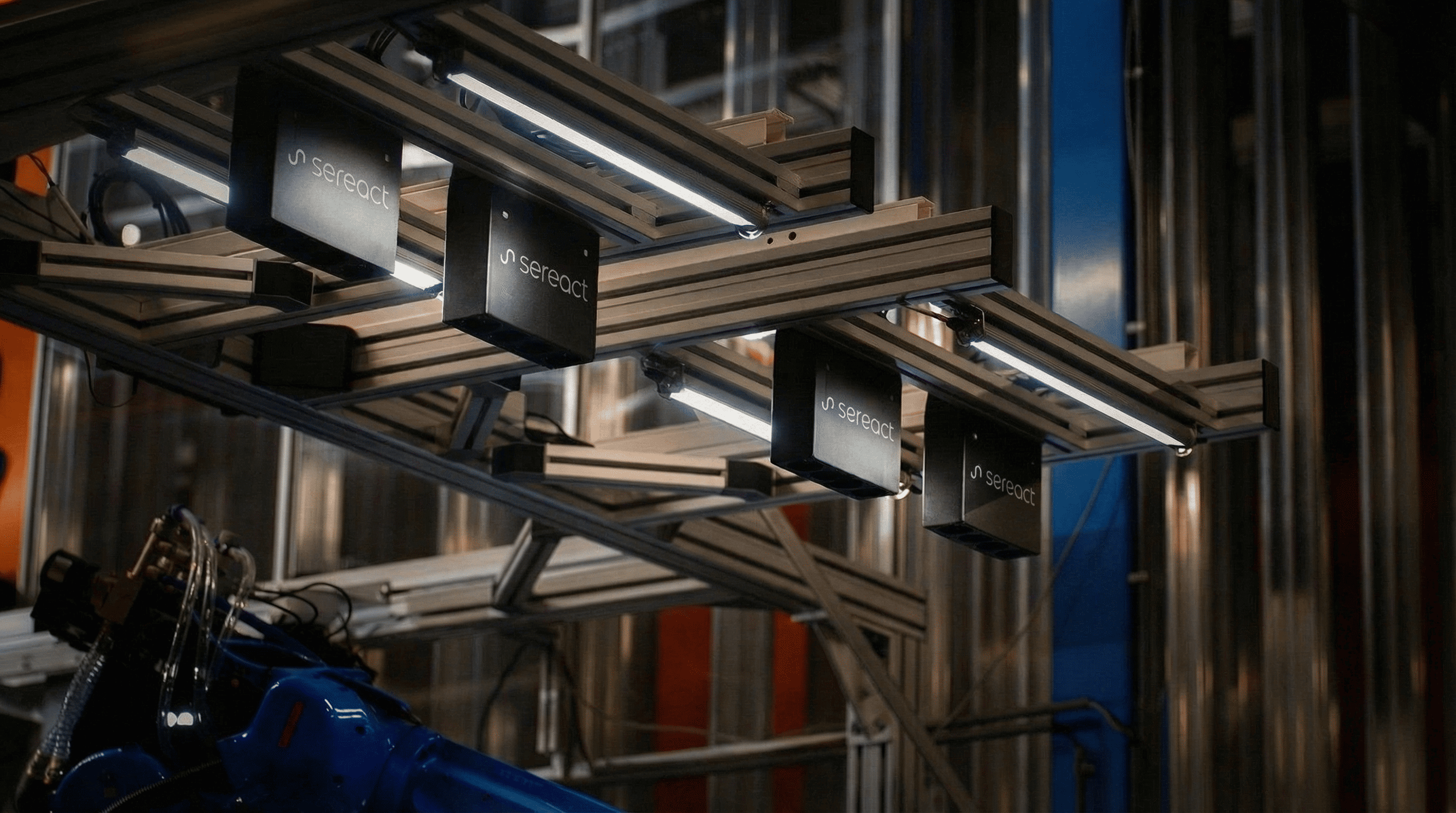

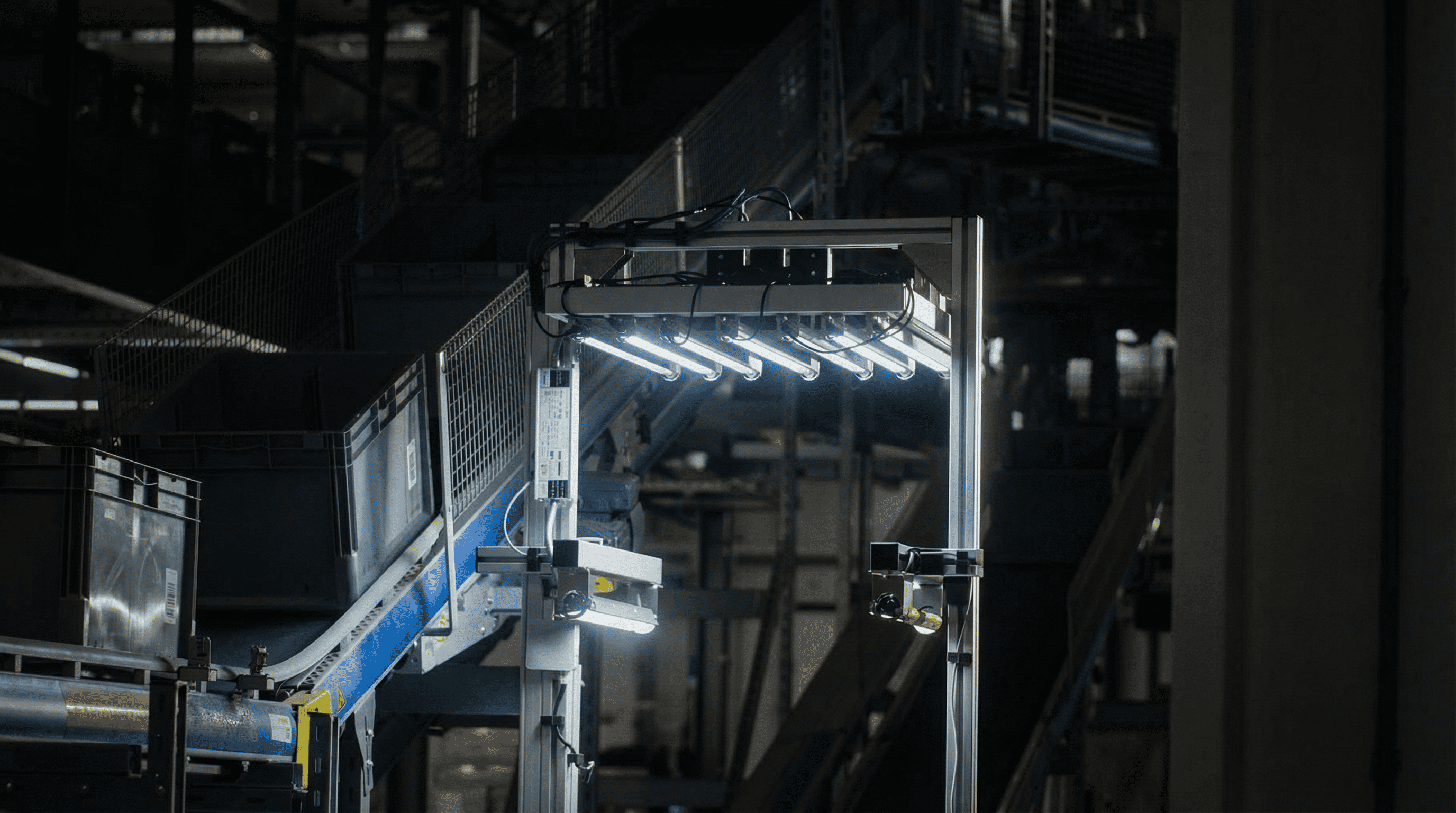

High-resolution stereo cameras positioned over bins and conveyors capture every critical moment. Lens reconstructs a detailed 3D point cloud from these images, delivering 2-3× higher resolution than standard industrial vision systems.

Lens capabilities

What Lens actually does in your warehouse

Traditional vision systems detect. Lens understands. Trained specifically on warehouse operations, Lens turns every camera into a real-time intelligence layer your WMS or WES can trust. These are the capabilities operators use every day.

Use cases

- 1.

- 2.

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

- 9.

- 10.

Instantly counts and verifies all items in a bin or tote. even with mixed SKUs, overlaps, or transparent packaging. Eliminates manual counts and shipping errors.

Where Lens delivers intelligence

Strategic installation points for maximum impact

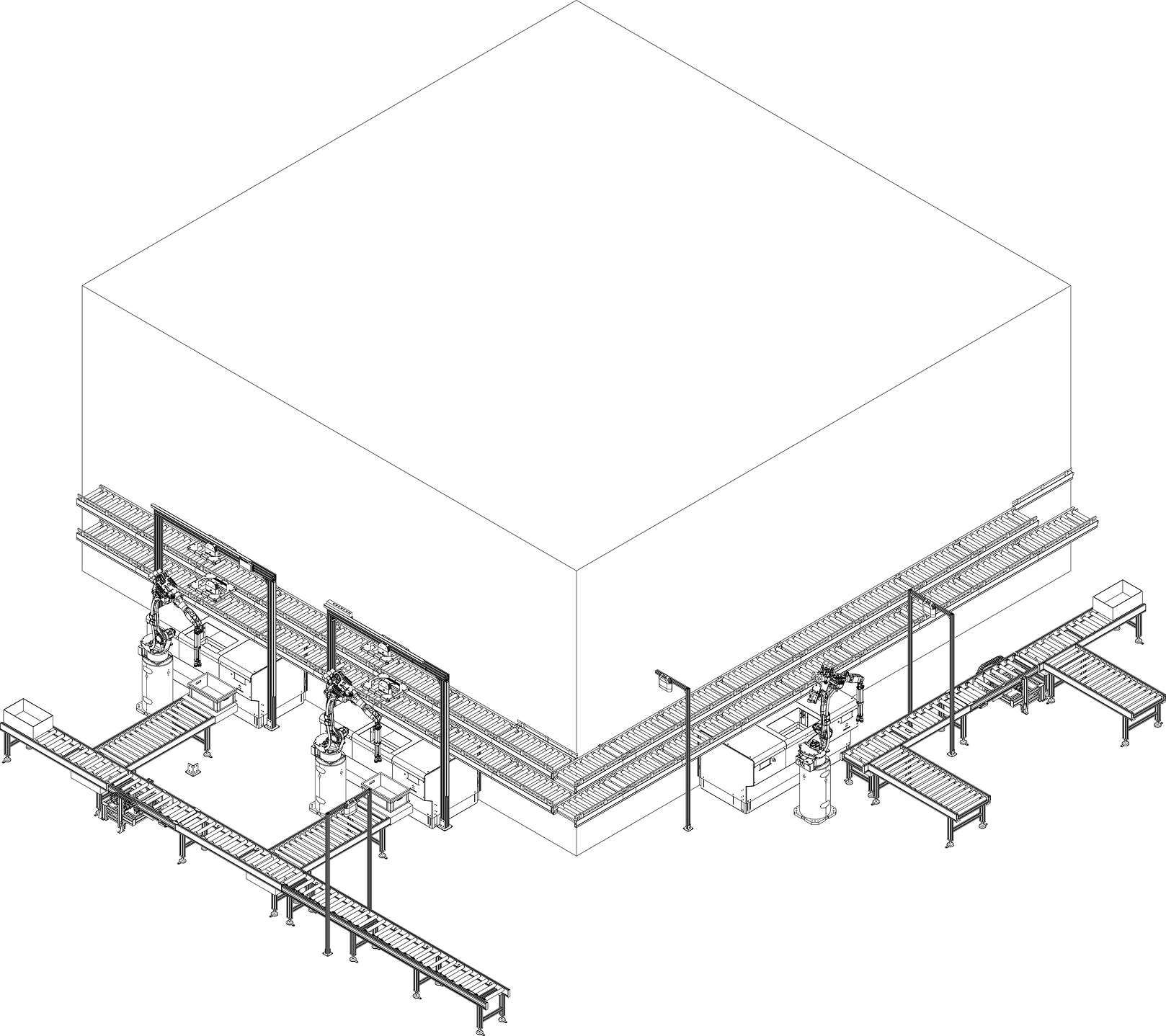

Lens transforms existing infrastructure into intelligence nodes. Mounted over bins and conveyors, our high-resolution cameras capture the moments where errors typically occur and decisions matter most.

Goods receipt intelligence

Transform receiving from reactive to proactive. Lens verifies ASN accuracy, detects damage before putaway.

- •

Damage detection at arrival

- •

Quantity validation

- •

Quality documentation

Storage & retrieval intelligence

Maintains perpetual inventory accuracy without manual counts. Every bin movement verified.

- •

Pick accuracy verification

- •

Cycle count elimination

- •

Bin optimization

Outbound quality control

Final checkpoint before customer impact. Ensures order accuracy and documents condition.

- •

Order verification

- •

Photo documentation

- •

Shipping validation

Returns intelligence

Transform returns from cost center to efficiency driver. Instant condition assessment.

- •

Original order matching

- •

Fraud detection

- •

Processing acceleration

The Tech

Why Lens succeeds where generic vision systems fail

Superior resolution & performance

Lens captures what standard industrial vision misses. Higher resolution and HDR deliver reliable perception even in poor lighting, clutter, and mixed SKUs.

- •4K+ resolution

- •HDR for challenging lighting

Warehouse-trained AI

Lens is not generic computer vision. It is trained on real warehouse data, so it understands how inventory behaves in practice.

- •Warehouse-specific training

- •Continuous learning

- •Context-aware perception

Real-time decision engine

Lens does more than detect. It decides. Visual input turns into actions in milliseconds, enabling true automation without manual checks.

- •Sub-second decision making

- •Rule and confidence logic

Native integration architecture

Lens fits into your existing stack without friction. API-first design connects directly to WMS, WES, WCS, and automation systems.

- •Webhook architecture

- •Real-time system updates

Case Study

Use cases across industries

Integration Ecosystem

Lens connects to everything in your warehouse

Warehouse Management Systems

Native integrations with leading WMS platforms. REST APIs for custom systems. Real-time inventory updates, order verification, and exception handling.

Execution & Control Systems

Feed intelligence to execution layer. Route exceptions, optimize workflows, trigger automations based on visual verification.

Robotics & Automation

Guide robots with validated data. Verify picks, prevent errors, ensure safe handling. Works with any automation platform.

Where the money leaks and what Lens fixes

Shrinkage

€200K-€500K lost yearly

- •Missing items

- •Damaged items

- •Unverified bin contents

Lens impact: Detects incorrect items, damage, and loss at the moment it happens.

Inventory errors

€150K-€400K lost yearly

- •SKUs in wrong bins

- •Quantity mismatch

- •Misaligned master data

Lens impact: Accurate count and real location of every SKU as it moves.

Stock-outs

€300K-€800K lost yearly

- •WMS believes stock is available, reality disagrees

- •Order cut-outs

- •Lost revenue and emergency replenishment

Lens impact: Real-time visibility into what is actually in the bin and on the shelf.

Picking mistakes

€250K-€600K lost yearly

- •Wrong item

- •Wrong colour or size

- •Wrong condition (damaged, open packaging)

Lens impact: Validates the correct item before it leaves the station.

FAQ

General Questions

Technical Questions

Integration Questions

Operational Questions

Data & Security Questions

Competitive Questions

Transform your warehouse into an intelligence-driven operation

See how Lens can eliminate inventory blindness, accelerate operations, and feed trusted data to every system in your warehouse. Our 15-minute technical demo shows Lens working with your specific use cases.

What you'll see in the demo:

- •Live counting demonstration with mixed SKUs

- •Damage detection in real-time

- •Integration with your WMS type

- •ROI calculation for your operation

- •Pilot program planning