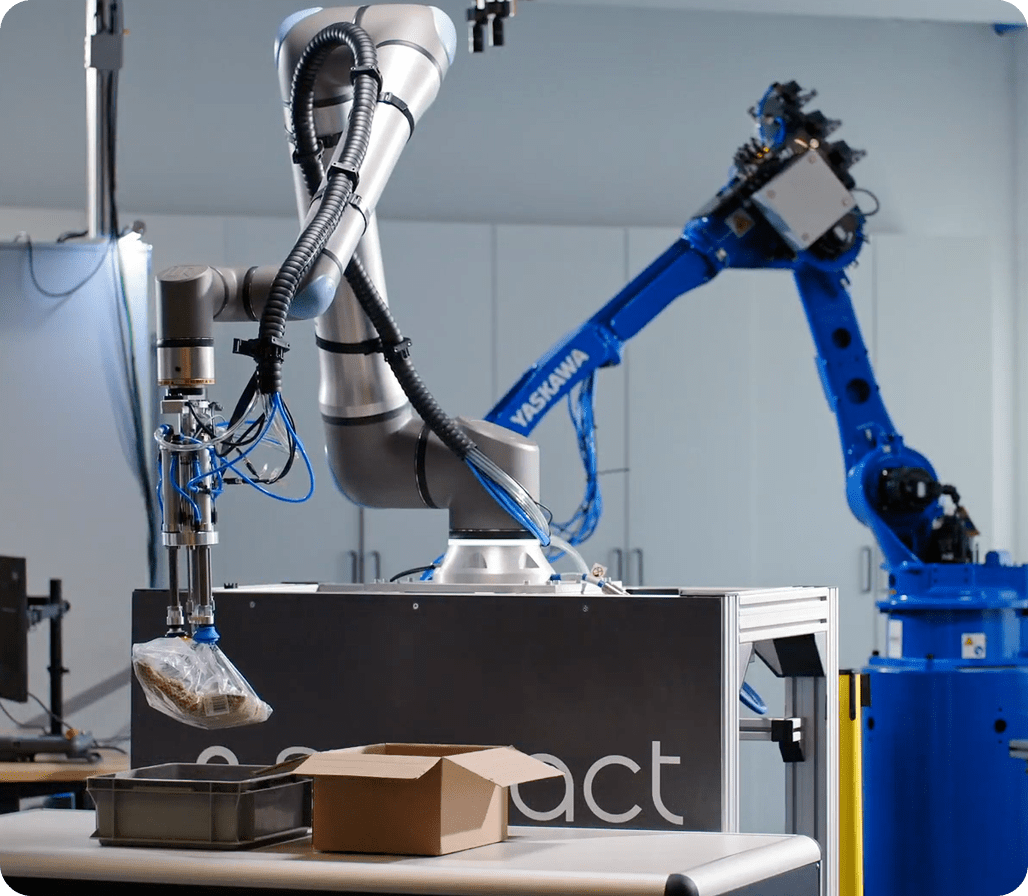

Automate picking. See everything.

Powered by AI. Delivered as Automation.

Cortex, the AI brain

One intelligence layer that learns every day

Cortex makes robots adaptive. It runs on Vision-Language-Action models that let it see, read, and act in one connected system. One brain can:

- •

Control industrial arms to pick new SKUs without retraining. Run Lens apps that check condition, spot anomalies, and predict risks.

- •

Share learnings across stations so the whole system gets smarter.

- •

Because it's one foundation, you don't bolt on separate systems for each task. Cortex compounds intelligence across your warehouse.

Zero code configuration for common cells. Standard interfaces to WMS and WES.

See it in production

"With Sereact we expanded our product range by thousands of items while keeping operations running smoothly. The robot simply works side by side with our team, like it's always been here."

"Our employees are proud to work alongside the robots. With Sereact, we're taking real steps toward a zero-touch fulfillment strategy."

"With Sereact we launched our first picking arm in just three months and it's improving every day through self-learning AI."

We'll match you to the most relevant live reference.

Why it pays off

ROI that compounds beyond speed

Day-one reliability. Robots show up every shift. No breaks. No overtime.

Fewer errors. Every mis-pick avoided saves money and trust.

More hours available. One cell can run two to three shifts without adding headcount.

Improves over time. Cortex and Lens learn your SKUs and flows, so value grows.

Certifications and compliance

Security is table stakes. Role-based access, encrypted data in motion and at rest, audit logging, and supplier controls are our operating baseline.

ISO/IEC 27001:2022

SOC 2 Type II.

FAQ

What is a piece picking robot and how is it used with AS/RS like AutoStore?

Why do you need AI for warehouse picking instead of rules or templates?

Is AI as good as humans at common picking tasks?

How is the AI trained and how fast does it improve on new SKUs?

What are the building blocks of a piece-picking cell?

How does AI inventory monitoring differ from traditional cycle counting?

Can AI be used for inventory management and anomaly detection inside a WMS?

Can robots handle delicate or deformable items?

What if my upstream system starves the robot?

How long to go live and see value

What's the IT effort

Self-check: Is my process a fit

You can sanity-check fit in 2 minutes. If you answer "yes" to most of the below, you are a strong candidate for a pilot.

We have multiple workstation that presents items in totes, bins, or cases on a repeatable cadence.

Our WMS/WES can assign work to a cell and receive confirmations or we can add a light middleware.

Our order mix has many each-picks where we value fewer errors, more hours, and consistent throughput.

Our items are mostly within safe weight, size, and surface limits for suction gripping. Challenging SKUs can be routed to manual or handled with recipes.

Upstream can stage the next tote before the current pick ends so the cell is rarely idle.

We can dedicate a small footprint for guarding and a technician for exception handling across several cells.

For Lens: we want documented QC at goods receipt and goods issue, continuous SLC inventory, and faster returns triage.

Ready to eliminate errors and idle time

In 15 minutes we will map Cortex and Lens to your stations and give you a quick ROI view.