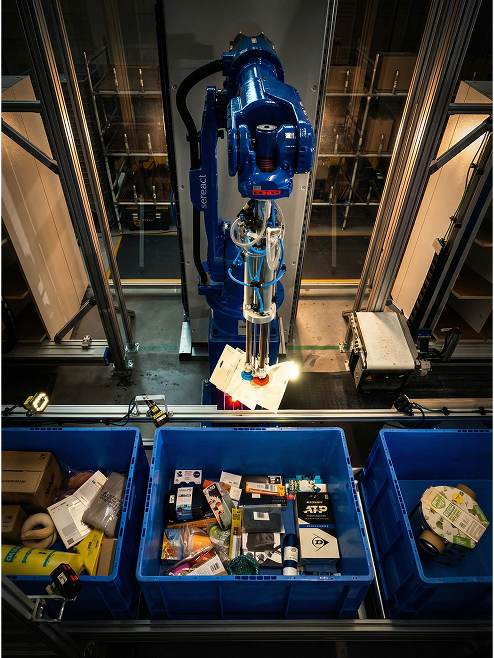

Robotic Putwall.

At Production Scale.

Turnkey solution to automate your order fulfillment. Cortex-powered robots pick from mixed totes with verified accuracy.

Integrated.

Intelligence.

Core system components

Throughput.

Engineered.

Economic Drivers

Forget abstract UPH claims. The station pays back when it replaces multiple shifts of manual batch picking, sorting, and consolidation without pushing errors downstream.

Feed rate from conveyors

The wall runs as fast as upstream batch picking can supply items. Sustained throughput above 350-450 units per hour depends on a steady feed. When feed stays predictable, Both shuttles remain utilised and output stays stable.

Order mix and batch structure

Larger, well-formed batches reduce compartment turnover and keep the wall full. Fragmented batches increase resets and slow the cycle. Strategic batching is a key factor in sustaining high performance rather than short bursts.

Parallel item positioning

Throughput depends on overlapping item positioning with placement. While one item is placed, the next is prepared. This parallelisation removes idle time and avoids the stop-start behaviour that typically caps manual throughput.

Packer capacity

Downstream packing must keep up with the sort rate. When packers lag, compartments fill, and the system slows upstream. Balanced packing keeps throughput flat, predictable, and fully autonomous.

Execution.

Guaranteed.

Operational Standards

Error Prevention

Robotic accuracy ensures the right item type and count lands in the compartment every single time.

Audit Ready

Every pick and every placement is logged with an image. Claims shrink because you have indisputable evidence.

Active Uptime

Real-time monitoring and proactive alerts keep uptime high while fitting strictly into your enterprise IT policies.

Field.

Evidence.

Success Stories

Questions.

Answered.

General FAQ