Physical AI that works

where it matters most.

Cortex delivers real autonomy on the warehouse floor. Live in production environments, zero supervision, infinite precision.

Trusted by

operators

worldwide.

From global logistics leaders to emerging enterprises, we provide the intelligence that powers modern fulfillment across five continents.

Intelligence

by the numbers.

Real production picks

Live systems across Europe and the US

Remote support intervention

Pick success

Typical throughput

Peak throughput above

With optimised feeds

1 robot replaces

Depending on shift pattern

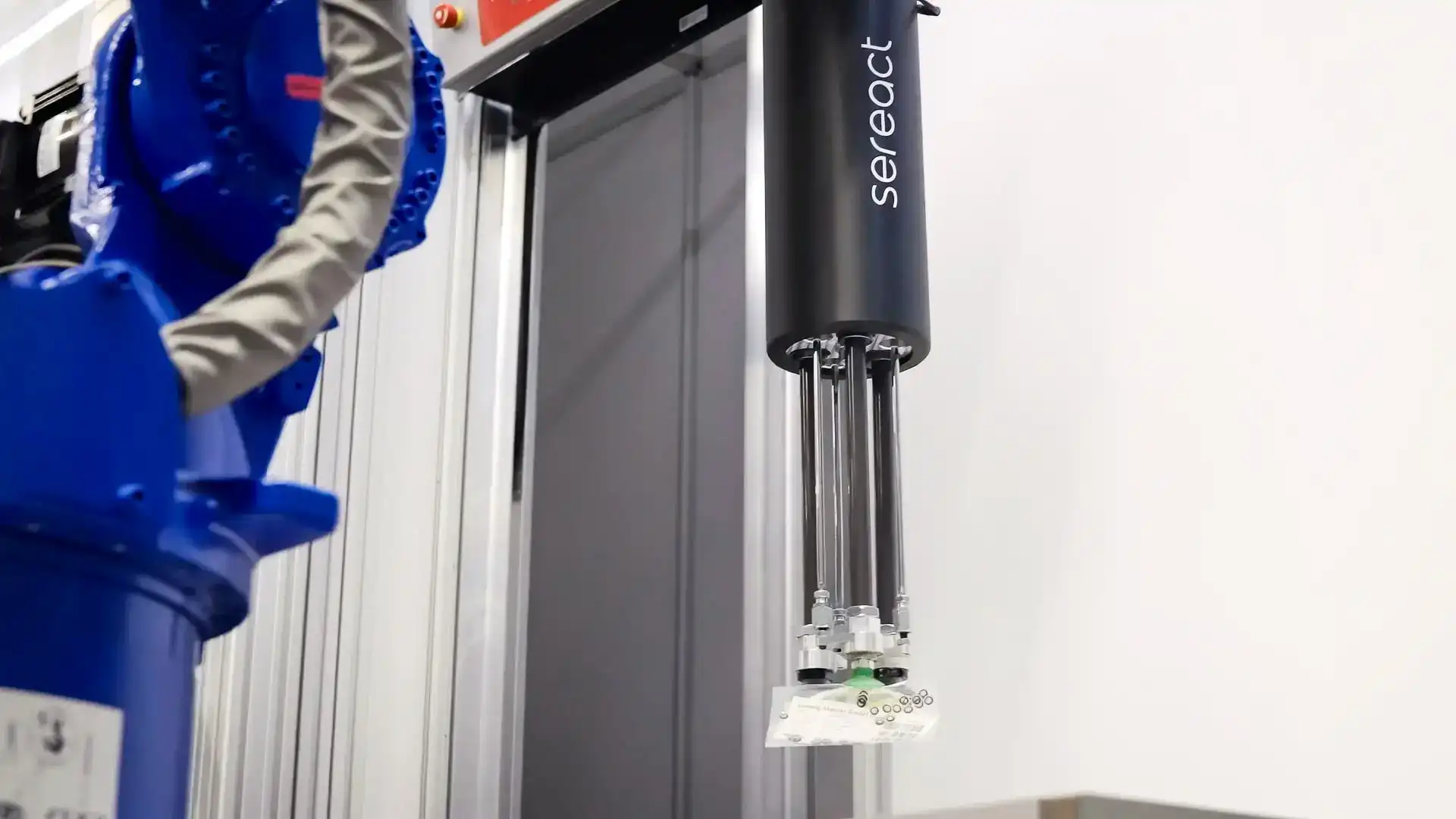

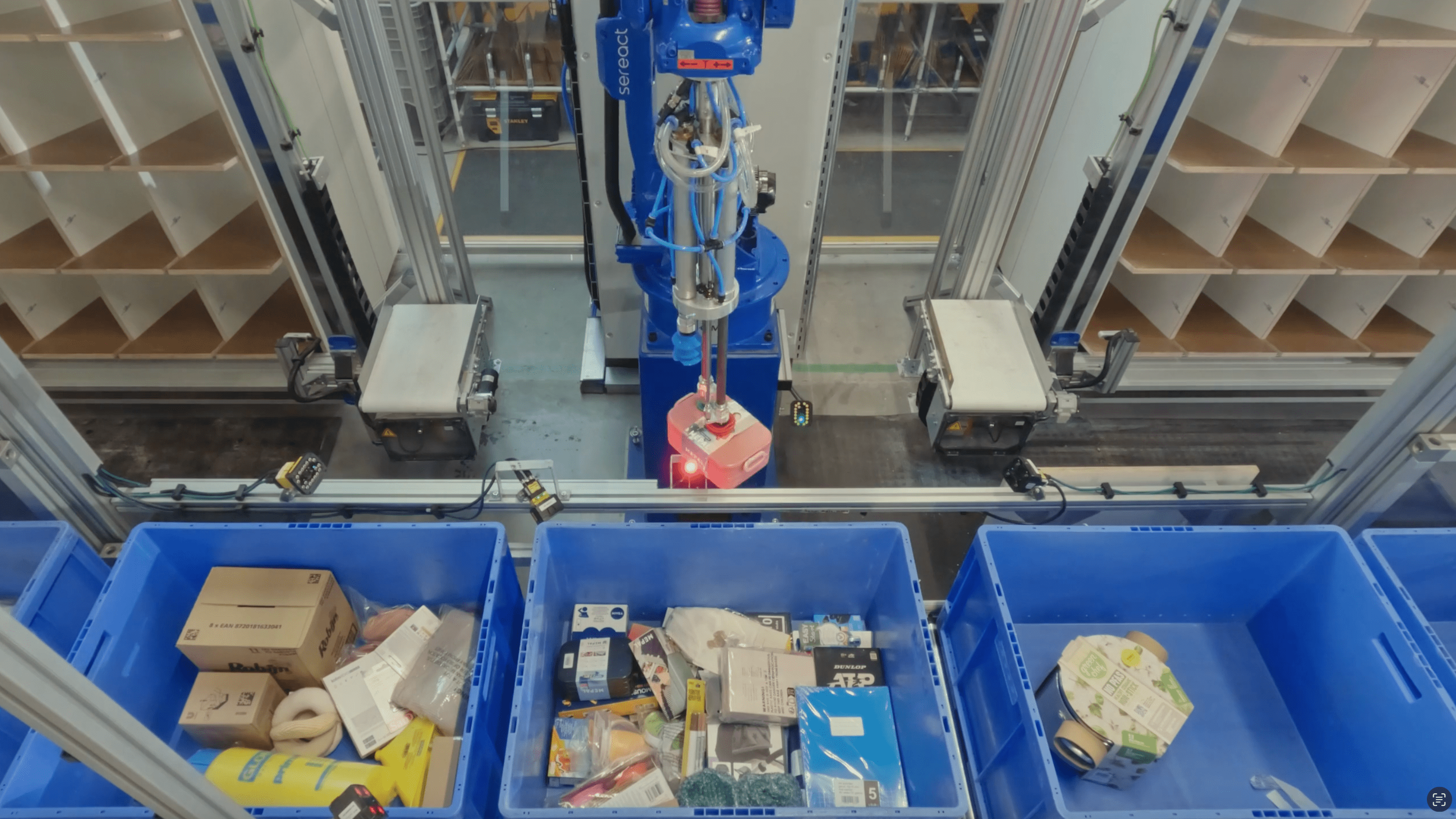

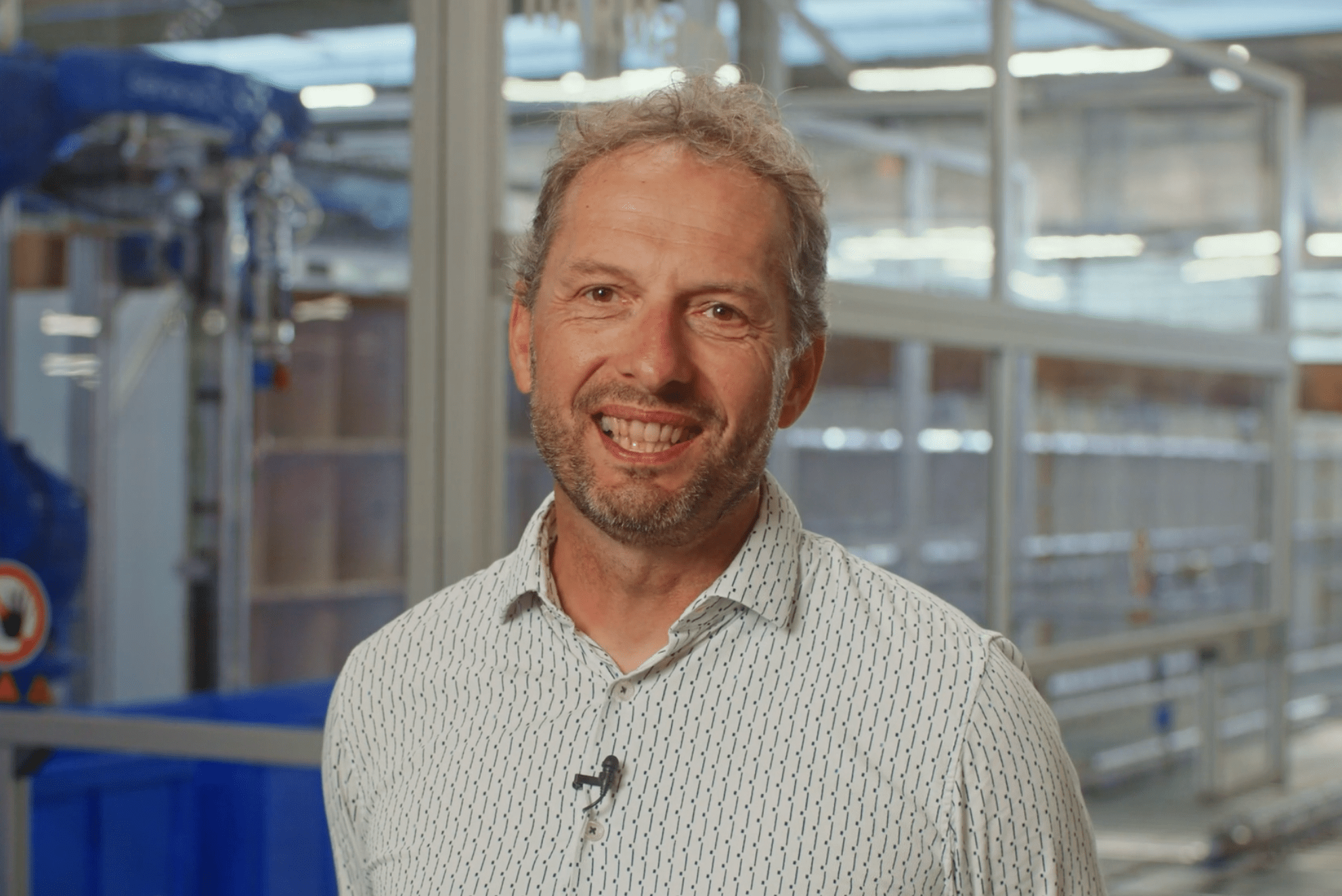

Sereact

in action.

The industrial

reality.

Industrial operations change daily. SKU mix shifts. Labour fluctuates. Traditional automation cannot adapt fast enough to the dynamic nature of global trade.

Sereact gives robots the intelligence to handle real conditions at scale, transforming static systems into autonomous operators.

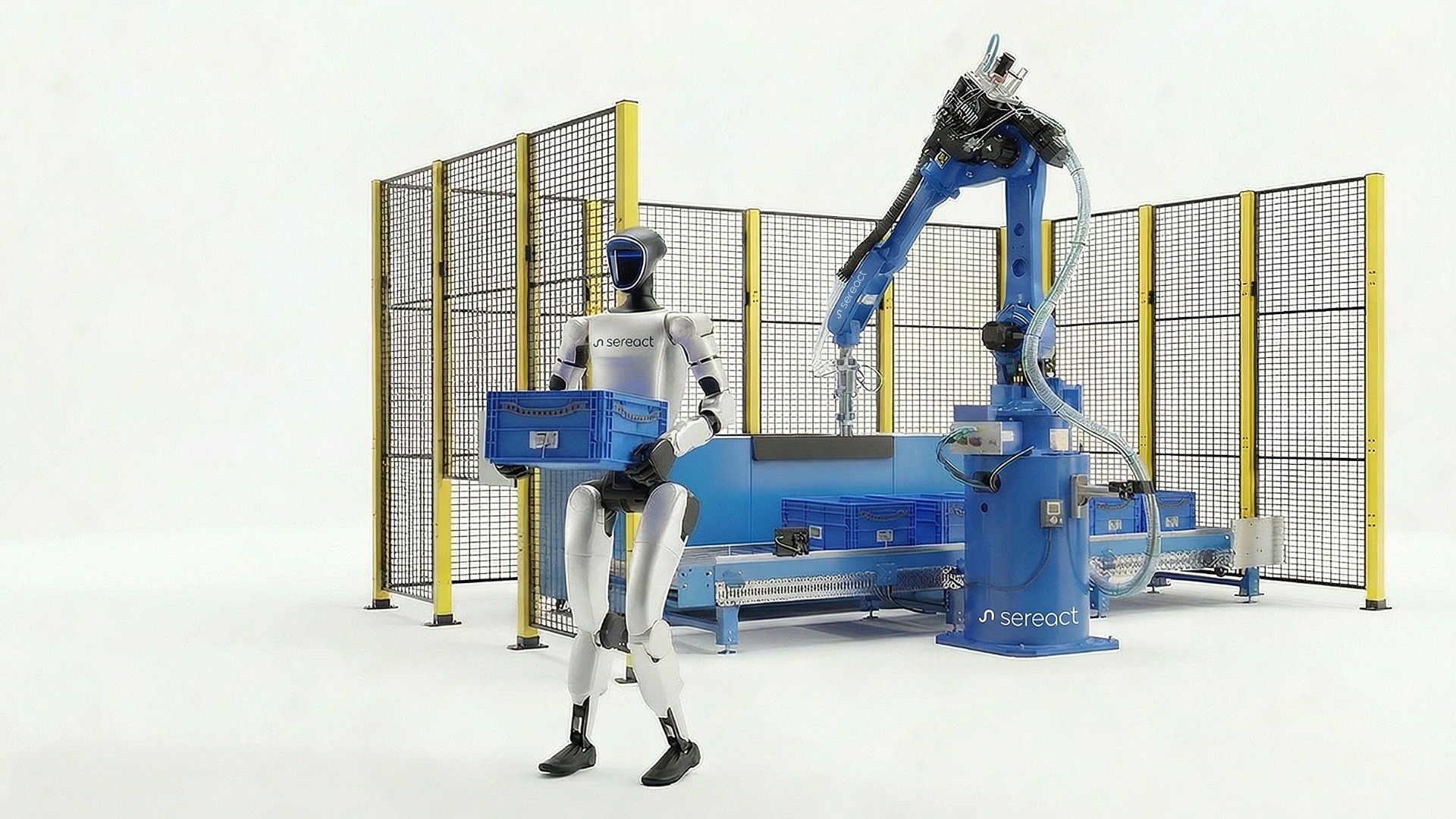

Zero-shot adaptation across standard 6-axis and humanoid architectures. Ready for deployment in brownfield sites.

The AI layer

for autonomous robotics.

One production model powering picking, placing, sorting, and inspection. No retraining. No tuning.

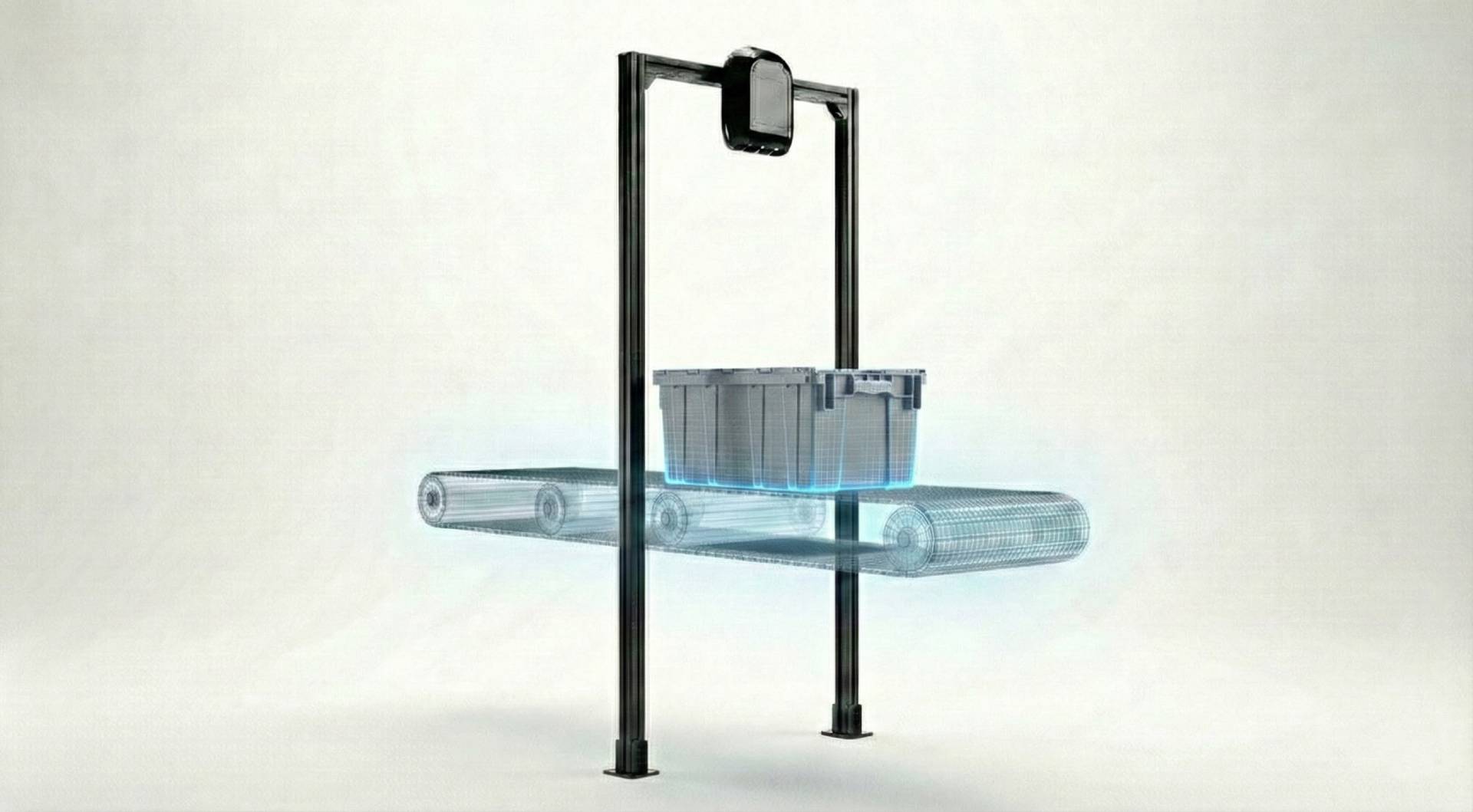

Lens

Real-time edge vision for inventory awareness. Detects damage, anomalies, and packaging issues with zero manual inspection.

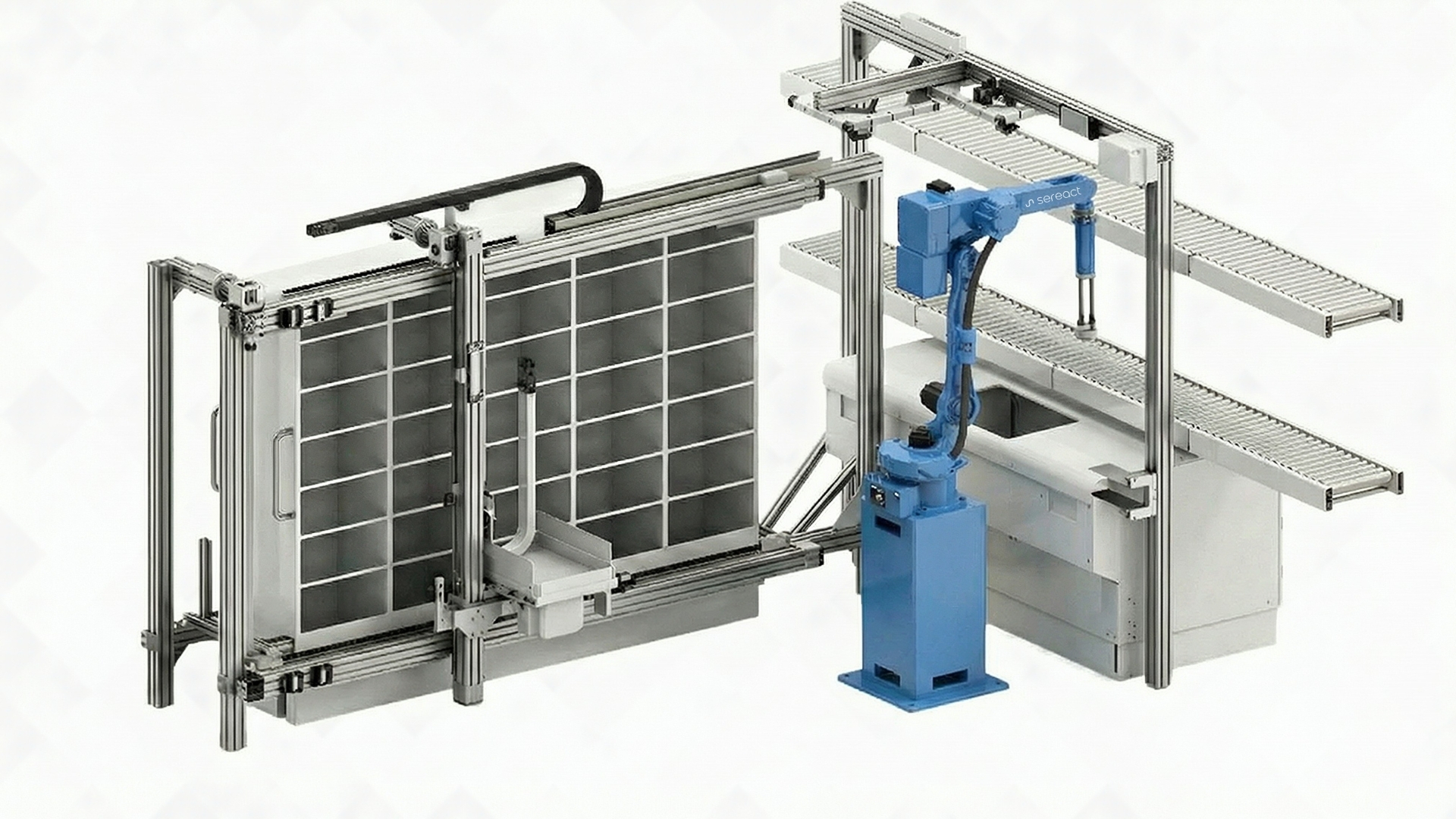

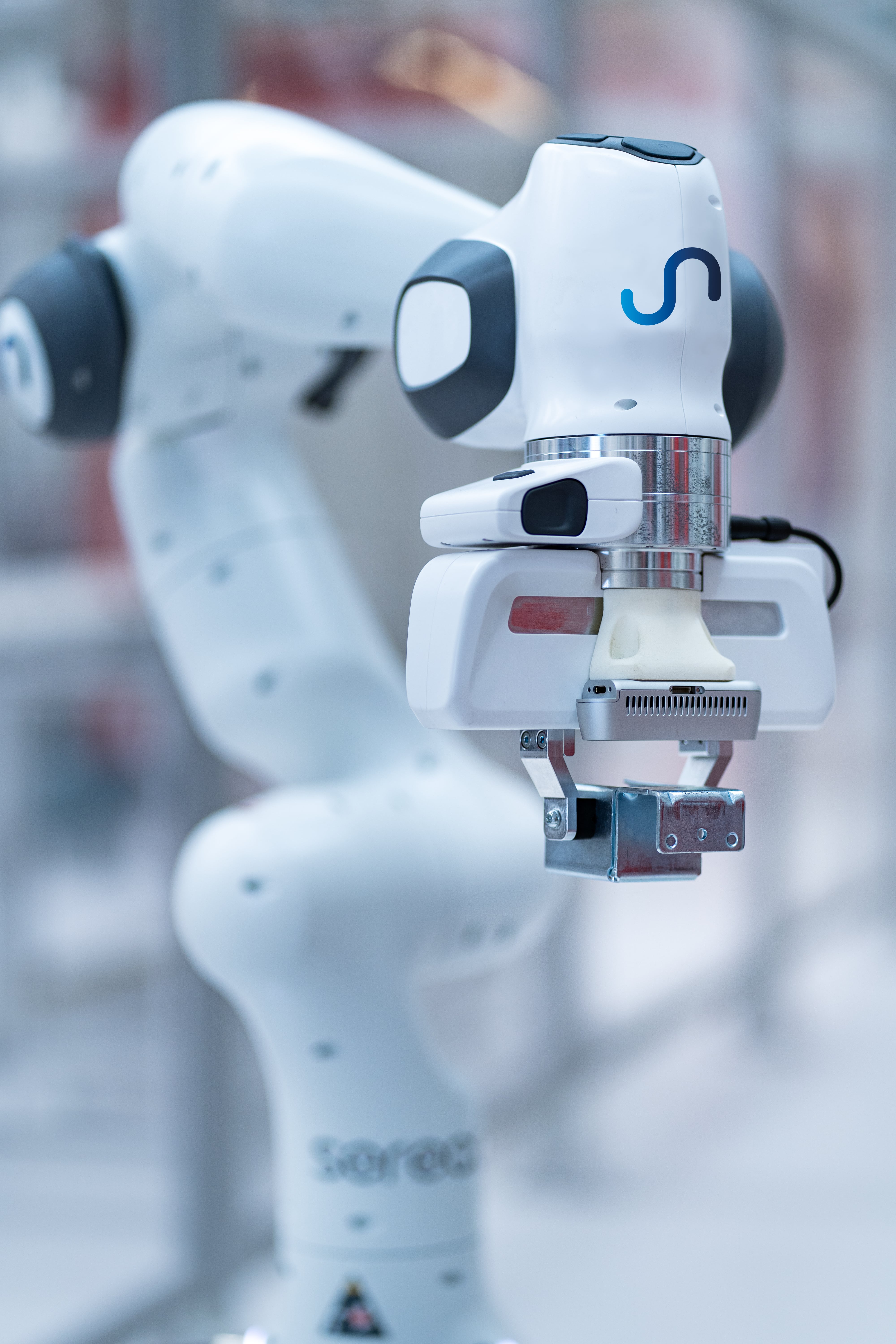

Robotic Picking

Autonomous picking across thousands of SKUs. Zero-shot handling of new items with any robotic platform.

Putwall Automation

Automated sortation for batch picking and returns. Consistent performance even with mixed items.

Humanoids

Embodied AI for human-like dexterity. Handle picking, sorting, and packing across changing tasks.

Return Handling

Automated inspection and sorting of returns. Identify condition and route items correctly at scale.

Not robots.

Results.

Reduce Expenses

Labour costs keep climbing, especially with overhead.

Cut up to 77% of costs with AI-powered picking. No retraining, no retooling. ROI in weeks.

Overcome Labour Shortages

Hiring is harder than ever, and peaks crush your capacity.

Sereact runs 24/7 with no supervision, scaling throughput without extra headcount.

Increase Productivity

Other robots need retraining and constant tuning.

Sereact installs in a day, works autonomously, and delivers 98%+ accuracy from the first pick.

Intelligence

for results.

Sereact doesn't just automate tasks, it gives robots the intelligence to handle reality. Fully autonomous from day one.

Most robotics AI only works in controlled lab conditions. Sereact's Vision Language Action Model (VLAM) is trained on millions of real-world picks, making it the first production-ready AI brain for robots.

System Monitoring

Real-time awareness.

Most robotics AI only works in controlled lab conditions. Sereact's Vision Language Action Model (VLAM) is trained on millions of real-world picks, making it the first production-ready AI brain for robots.

System Monitoring

Real-time awareness.

Precision

by design.

Outcomes

that matter.

Tangible ROI driven by industrial-grade AI. We turn robotic potential into production reality.

Lower overhead.

1 robot replaces 3 to 4.5 FTE depending on shift pattern. Customers save up to €111,000 per month.

Increase volume.

98% first-attempt pick success with peak speeds above 650 UPH. High availability across all shifts.

Scale autonomously.

Autonomous 24/7 operation with minimal human interventions. Predictable performance at any scale.