Automated inventory control: inventory monitoring with AI

Automated inventory control: how AI makes warehouse management more efficient

A lack of transparency in inventory management is one of the biggest problems in logistics. Companies invest in modern warehouse systems, automation and robotics - but inventory monitoring often remains incomplete. The consequence: inaccurate inventory data, inefficient processes and high costs. AI-based inventory control enables more precise monitoring of stock levels and helps to eliminate sources of error.

What is automated inventory control?

Automated inventory control refers to the use of technologies such as artificial intelligence and image recognition to continuously monitor inventory levels. Unlike manual inventories or static ERP systems, an AI-based solution is dynamic and updates inventory data in real time.

The key features of automated inventory monitoring are

- Capture real-time inventory levels without manual intervention

- Identify inventory discrepancies and automatically adjust data

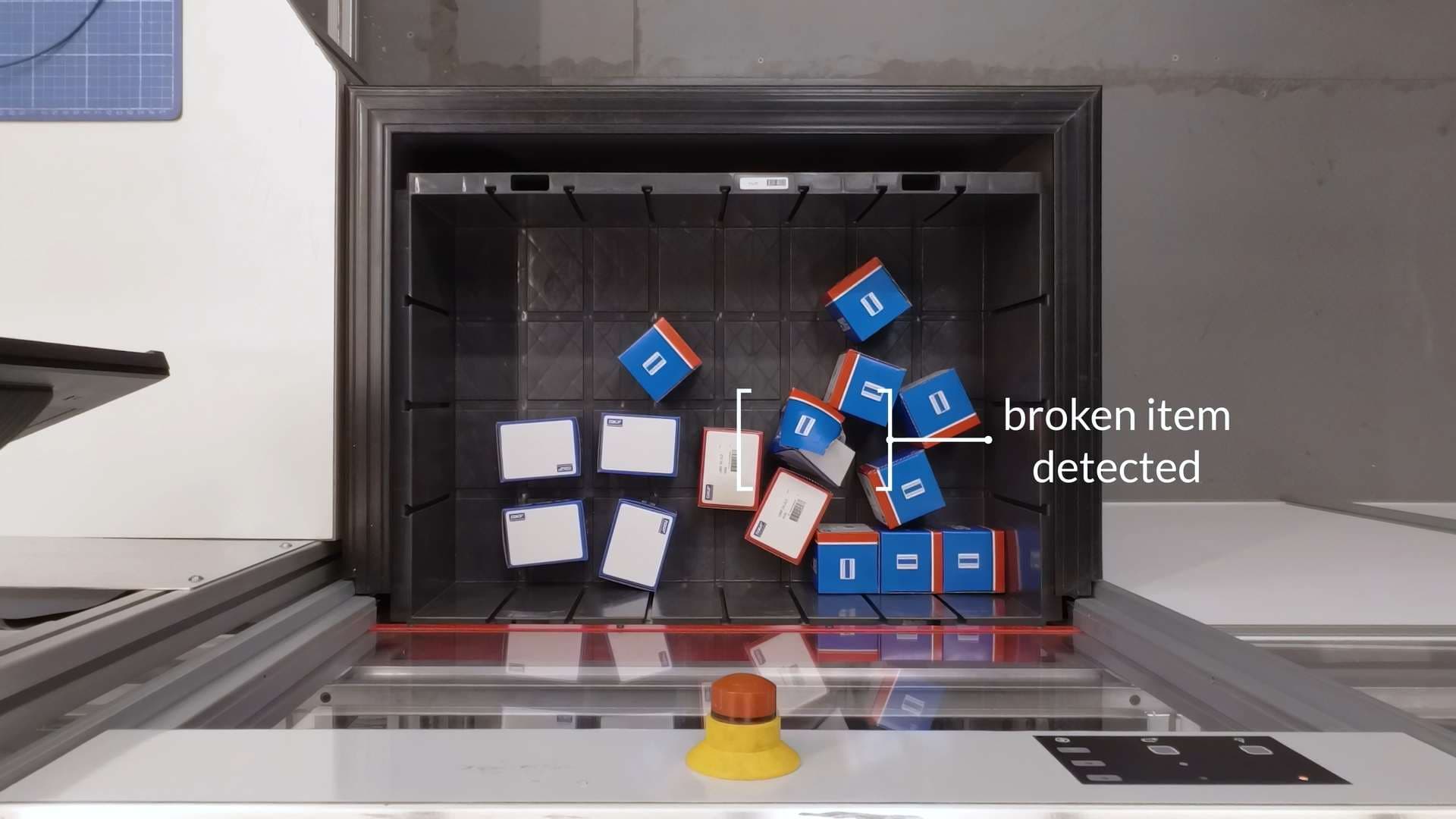

- Detect damaged or misplaced items with image recognition and AI-based analysis

Real-time data acquisition with artificial intelligence

While conventional systems often rely on barcodes or RFID technology, artificial intelligence enables visual inventory monitoring. With the help of camera systems and image recognition software, AI can analyze stock levels, identify items and assess their condition.

A major benefit of real-time data collection using AI is that it continuously tracks inventory, eliminating the need for manual inventory tracking and increasing efficiency. The system also reduces errors by detecting missing or misplaced items immediately. The seamless documentation and analysis of all inventory movements also improves planning. By automating these processes, companies can save time and use resources more efficiently.

Benefits of AI-based inventory monitoring

Leveraging technologies like artificial intelligence for inventory management offers many benefits to businesses:

- Increase inventory accuracy: Eliminate manual errors so inventory data is always up to date.

- Reduced inventory costs: More accurate inventory management eliminates excess inventory.

- Less delivery problems: Accurate inventory data can improve delivery times, reduce error rates, and increase customer satisfaction.

- Reduced labor costs: Automation significantly reduces the need for manual inventory checks.

- Seamless integration: AI systems can be integrated with existing warehouse management systems and combined with robotic solutions.

AI-based inventory monitoring in action

Many companies face the challenge of managing inventory efficiently without relying on manual processes. Sereact Lens is an AI-based solution that enables accurate, automated inventory control. Using camera systems and intelligent image recognition, the system analyzes stock levels in real time and ensures maximum transparency.

How does Sereact Lens work?

Sereact Lens combines high-resolution cameras with powerful artificial intelligence.

The system works in three steps:

- Recording: Camera systems record current inventory levels and document all items.

- Analyze: AI processes the image data, recognizes items, verifies quantities, and identifies potential errors.

- Act: Based on the captured data, inventory adjustments are automatically made in the warehouse management system (WMS). If action is required, the appropriate personnel are automatically notified.

Sereact Lens not only detects missing or faulty items, but can also identify damaged packaging, incorrect labeling, or varying quantities. By fully automating these processes, inventory errors are minimized and warehouse operations are made more efficient.

Integration with warehouse management systems and picking robots

In addition to being a stand-alone system, Sereact Lens can be seamlessly integrated into existing warehouse management systems (WMS) and automated robotic systems. This allows companies to feed real-time inventory data into their WMS for an accurate view of inventory levels at all times. The system immediately detects out-of-stocks or incorrect deliveries without the need for manual verification. Picking robots can be targeted by AI to automatically locate anomalies and make corrections.

This integration enables fully automated warehousing to minimize sources of error and make processes more efficient.

Applications and Benefits of AI-Based Inventory Control

Automated inventory control with artificial intelligence can be used in many areas of logistics, including receiving, warehousing, and shipping.

Continuous inventory without interrupting operations

Many companies conduct inventories once a year or at regular intervals. The problem is that inventory levels can change unnoticed between inventories. Out-of-stocks, misplaced items, or undetected losses lead to inaccurate inventory data.

AI-based inventory monitoring enables continuous, concurrent inventory. Automating these processes eliminates the need for time-consuming manual inventories.

Optimize returns management

Returns are a major cost factor for companies, both financially and organizationally. AI-based systems improve returns management by automatically capturing returns and instantly checking whether they are intact and reusable. This means that inventory levels can be updated and adjusted without errors directly in the system. Automating the replenishment process also significantly reduces labor costs.

Conclusion - Why companies should rely on automated inventory control

Out-of-stocks, overstocks, and inaccurate inventory data cost companies time, money, and customers. Manual inventory is error-prone and costly, while unreliable inventory data brings supply chains to a standstill.

With AI-based inventory management, stock levels are recorded in real time, discrepancies are immediately detected, and processes are automatically controlled. This saves costs, reduces errors, and ensures accurate inventory management. Automating these processes gives companies a long-term competitive advantage and reliable warehouse logistics.

By making warehouse management more efficient, reducing operating costs, and ensuring reliable delivery, you not only increase process efficiency, but also customer satisfaction.

Article Resources

Access content and assets from this post

Text Content

Copy the full article text to clipboard for easy reading or sharing.

Visual Assets

Download all high-resolution images used in this article as a ZIP file.

Latest Articles