Robotic Putwall

Turnkey solution to automate your

order fulfillment.

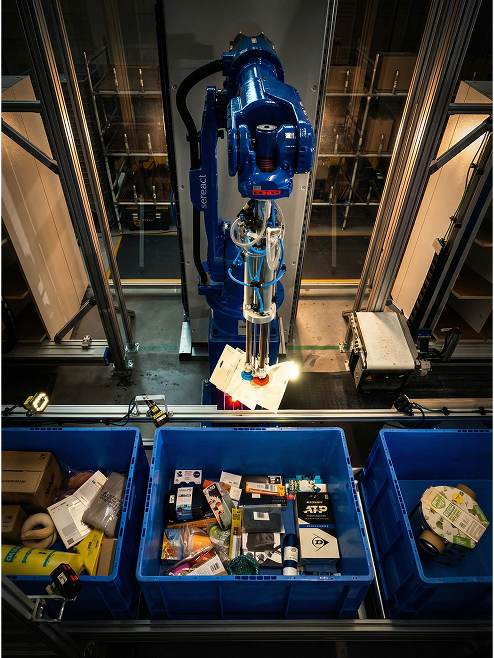

Cortex-powered robots pick from mixed totes. Lens verifies every item, reads barcodes where available, and logs an image. A miniload distributes to a putwall where packers close orders with photo verified accuracy.

Built for AutoStore ports, shuttle systems and conveyors in high mix e commerce and returns.

What the system actually does

Warehouses that batch pick struggle with two things.

- Feeding items fast enough to finish large batches.

- Closing orders without scanning errors, misplaced items, or packer slowdowns.

A robotic putwall solves both by running picking, verification, and order consolidation as one flow.

Here is the actual sequence

Sereact robots pick items from mixed batch totes.

Lens checks the right item for the right order using image plus barcode.

The system assigns each order to a putwall slot.

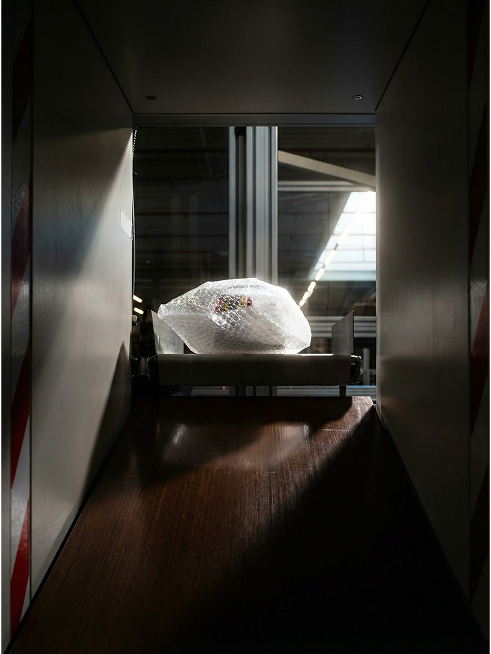

Shuttles deliver items to assigned putwall compartments without gaps.

Case Study

Why this version is different

Most putwalls depend on barcode scans and manual accuracy.

Most robotic picking systems end at item-in-tote and leave consolidation to people.

The Sereact system links the two seamlessly.

No per SKU teaching

Cortex handles polybags, cartons, and irregular items without templates. Your catalogue connects once.

Seamless integration

The system connects robotic picking with putwall consolidation, eliminating manual handoffs and reducing errors.

Real-time verification

Lens verifies every item as it moves through the system, ensuring accuracy at every step of the process.

Automated consolidation

Items flow directly from picking to putwall without manual intervention, streamlining the entire fulfillment process.

Performance and economics

Forget abstract UPH claims. The station pays back when it replaces multiple shifts of manual batch picking, sorting, and consolidation without pushing errors downstream. You get stable throughput, fewer touches, and photo-verified orders.

What drives throughput

Feed rate from conveyors.

The wall runs as fast as upstream batch picking and induction can supply items. In production, sustained throughput above 300-400 units per hour requires a steady feed. When induction fluctuates, the station throttles. When feed stays predictable, both shuttles remain utilised and output stays stable.

Order mix and batch structure.

Larger, well-formed batches reduce compartment turnover and keep the wall full. Fragmented batches increase resets and slow the cycle. In live operation, improving batch structure was a key factor in sustaining 300-400 units per hour rather than short bursts.

Parallel item positioning.

Throughput depends on overlapping item positioning with placement. While one item is placed, the next is prepared. This parallelisation removes idle time and avoids the stop-start behaviour that typically caps manual putwall throughput.

Packer capacity.

Downstream packing must keep up with the sort rate. At 300-400 units per hour, packing speed becomes the limiting factor if not sized correctly. When packers lag, compartments fill, and the system slows upstream. Balanced packing keeps throughput flat and predictable.

Operational reliability

Error prevention

Robotic accuracy ensures the right item type and count lands in the compartment every single time.

Audit ready

Every pick and every placement is logged with an image. Claims shrink because you have evidence.

Keep running

Real time monitoring, alerts, and remote support keep uptime high while fitting your IT policies.

Proven patterns from live sites

FAQ

What happens during batch changeover

Can it handle damaged packaging

How many orders at once

What about small items

Power and air

Integration timelines

Break even

Subscription models