AI Vision.

At Every Bin.

Sereact Lens provides real-time AI perception for every bin, every order, and every return. Eliminate blind spots and keep your WMS honest with perpetual inventory verification.

The Blind Spot in Modern Warehouses

You've automated everything except knowing what's actually happening in your warehouse.

Modern warehouses run on data, but lose visibility at critical moments. Between scans, items get miscounted, damaged, or misplaced. Your WMS makes decisions on assumptions, not facts.

WMS says 10 items, reality is 9 — orders fall.

Damage happens between scans, discovered too late to fix.

Misplacements go unnoticed, stock counted in wrong locations.

Returns require manual inspection, hours of labour wasted.

Beyond Vision

From Capture to Action

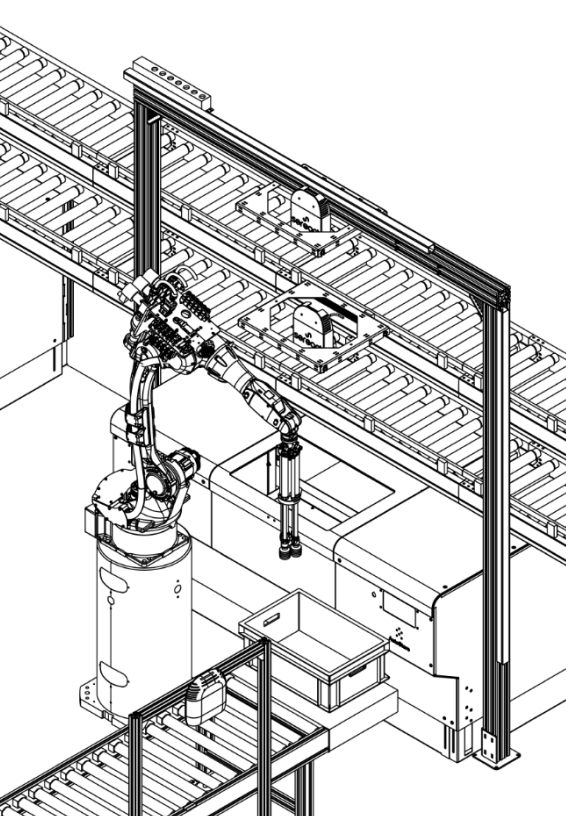

Lens is a complete intelligence platform that sits between your physical operations and digital systems. A real-time decision engine for production-critical environments.

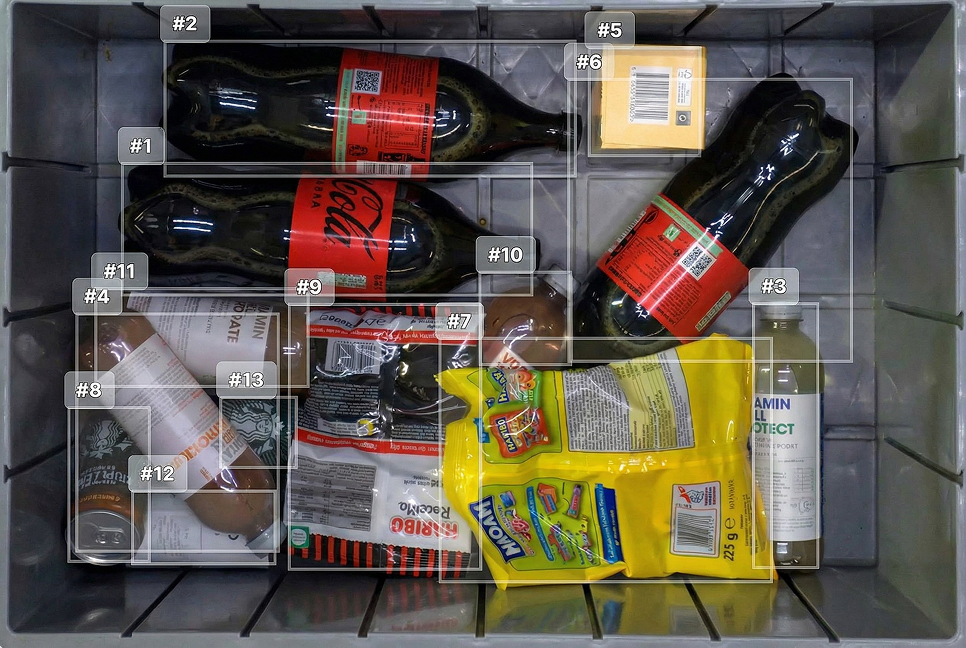

High-resolution stereo cameras positioned over bins and conveyors capture every critical moment. Lens reconstructs a detailed 3D point cloud from these images.

The Science of

Visual Truth.

Performance verified at scale

Superior resolution & performance

Lens captures what standard industrial vision misses. Higher resolution and HDR deliver reliable perception even in poor lighting, clutter, and mixed SKUs.

Warehouse-trained AI

Lens is not generic computer vision. It is trained on real warehouse data, so it understands how inventory behaves in practice.

Real-time decision engine

Lens does more than detect. It decides. Visual input turns into actions in milliseconds, enabling true automation without manual checks.

Native integration architecture

Lens fits into your existing stack without friction. API-first design connects directly to WMS, WES, WCS, and automation systems.

Native Integration.

Connects to everything

Lens fits into your existing ecosystem as a drop-in intelligence layer. No legacy changes required.

Warehouse Management Systems

Native integrations with leading WMS platforms. REST APIs for custom systems. Real-time inventory updates, order verification, and exception handling.

Execution & Control Systems

Feed intelligence to execution layer. Route exceptions, optimize workflows, trigger automations based on visual verification.

Robotics & Automation

Guide robots with validated data. Verify picks, prevent errors, ensure safe handling. Works with any automation platform.

Universal Application.

Capabilities for every station

Instantly counts and verifies all items in a bin or tote. even with mixed SKUs, overlaps, or transparent packaging. Eliminates manual counts and shipping errors.

Visual Verified.

Case Study.

Verified in Production

Broad industry applicability

Lens is deployed across diverse operational environments, from high-volume fulfillment centers to specialized manufacturing facilities.

Presence.

At Every Node.

End-to-End Visibility

Lens transforms existing infrastructure into intelligence nodes, capturing critical moments where decisions matter most.

Goods receipt intelligence

Transform receiving from reactive to proactive. Lens verifies ASN accuracy and detects damage before putaway.

Storage & retrieval

Maintain perpetual inventory accuracy without manual counts. Every bin movement is verified in real-time.

Outbound quality control

The final checkpoint. Lens ensures order accuracy, documents condition, and creates proof for every shipment.

Returns intelligence

Transform returns into efficiency. Lens assesses condition, matches original orders, and accelerates restocking.

The Cost of

Invisibility.

Yearly Loss

Shrinkage

Detects incorrect items and loss at the moment it happens.

Inventory errors

Validated count and real-time location of every SKU.

Stock-outs

Real-time visibility into actual bin and shelf availability.

Picking mistakes

Validates every item before it leaves the station.

Frequently Asked

Questions.

Ready for the

Next Era.

Transform your warehouse into an intelligence-driven operation. Lens integrates seamlessly with any WMS, WES, or automation platform via our high-performance REST API.

"Sereact Lens is the missing link between physical reality and digital inventory."