Reliable Picking.

At Any Scale.

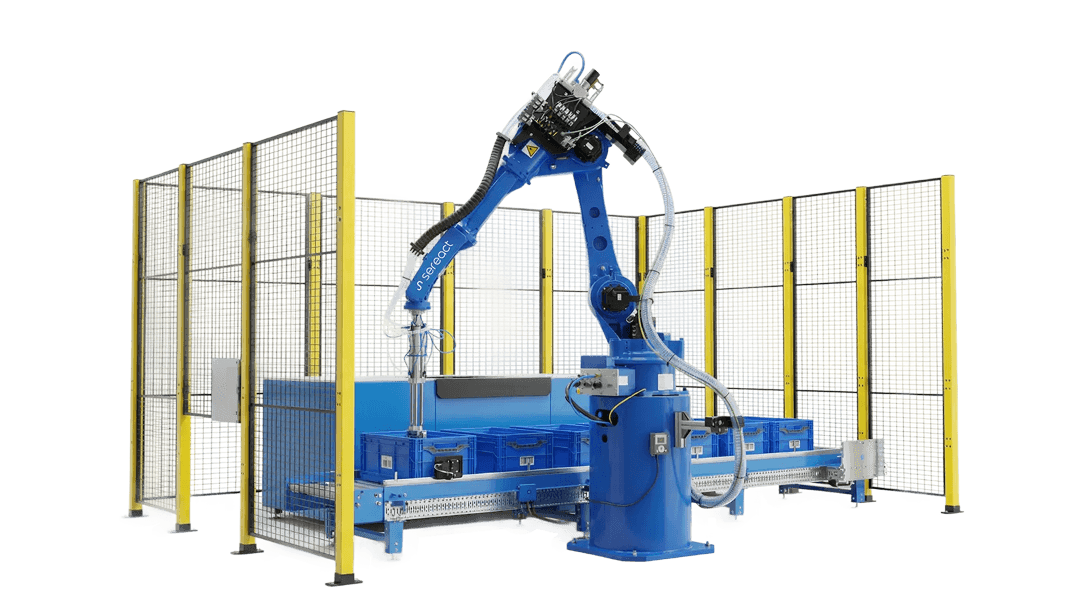

The first AI-powered picking system built for production-critical throughput. Zero retraining, hardware agnostic, and ready for 24/7 warehouse operations.

Key Production KPIs

Performance verified at scale

8,000+

One cell. No breaks. No shift change. No output drop.

600+

When your system can feed fast enough.

> 99%

Closed-loop, low intervention performance.

Why operators choose this system

Handles messy, mixed and unseen SKUs

Closed-loop control for consistent pick success

Works with AutoStore ports, shuttles, conveyors and AMR feeds

Built for uptime with robots running day and night in production sites

Case Studies

The Cost Per Pick Advantage

Picking decides your cost per order. The numbers speak for themselves. Automated throughput is the only way to decouple growth from labor costs.

Legacy Approach: Human Picker

450 UPH for short bursts

250 to 300 UPH across a full shift

Output drops after breaks and during peak

Higher error rates under pressure

Requires two or three shifts for full-day coverage

Modern Approach: Cortex-Powered

Stable 300 to 350 UPH every hour

8,000+ picks per day from one cell

Runs nights and weekends with no extra cost

Low error rates and low intervention

Predictable output for planning and SLAs

What Sereact Delivers

Zero-Shot Picking

Picks new items without training or teaching. No image sets. No onboarding downtime.

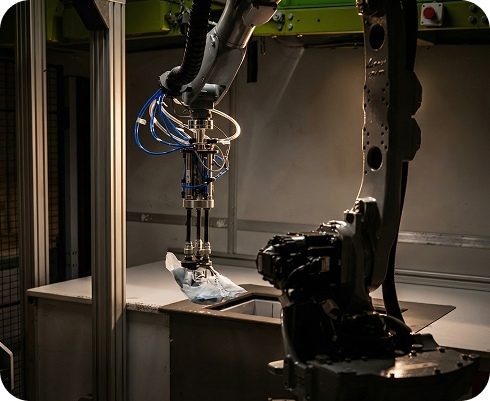

Closed-Loop Control

Cortex adapts grip, movement and placement in real time. If an item shifts, the robot corrects itself.

Low Intervention

The robot solves difficult items on its own. Your team only handles true exceptions, protecting throughput.

Feed Agnostic

Fits your AutoStore ports, shuttle systems, conveyors and AMR flows. No infrastructure changes required.

Lens Quality Check

Catches crushed, leaking or wrong items before placement. Prevents downstream errors and claims.

Industrial Uptime

Built for production. Runs reliably across nights, weekends and peak seasons at scale.

Hardware agnostic. Production verified.

How it fits the workflow?

Tote Arrives

AutoStore Carousel Ports or conveyors present a bin. Sereact integrates directly with your existing infrastructure.

Instant Perception

Our AI identifies each SKU and plans the optimal grasp in real time, even with mixed or deformable items.

Closed-loop Pick

The robot adjusts trajectory and grip dynamically. If an item shifts, the system recovers independently.

Lens Quality Check

Lens flags damage, anomalies, or incorrect items before placement to protect downstream throughput.

Final Placement

Items are placed precisely into cartons, totes, or onto conveyors. Seamless WMS/WCS synchronization.

How Exceptions Are Handled

Real warehouses are messy. Demo-ware fails there. Cortex is built with a deep understanding of physical uncertainty to keep your throughput high when items misbehave.

Real-time Self-Correction

Cortex monitors every pick in a closed loop. If an item slips, shifts, or collapses, the robot adapts its grasp plan instantly.

- Dynamic trajectory planning

- Automatic force adjustment

- No line stops or alarms

Smart Triage

When an item cannot be picked safely, the system marks it in the WMS and moves to the next task to protect throughput.

- Isolated tote marking

- Anomalous item flagging

- Continuous station operation

Remote Resolution

Most edge cases are cleared remotely by our support team in seconds, without requiring a floor technician.

- < 12 min average resolution

- Remote intervention APIs

- Production-grade uptime

Production Robotics vs. Demo Robotics

The difference is handling the edge cases without stopping the line. Cortex provides a self-healing picking layer that turns exceptions into structured data.

Technical Fit

Plug-and-play capability for modern fulfillment. Sereact picking cells work with your existing WMS and warehouse infrastructure without redesign.

Logistics Compatibility

Physical Envelope

Integration & Safety

Ready for your layout?

Our engineers provide full layout support and integration consulting. Zero-retraining means your facility is ready today.

The real AI revolution is on the

warehouse floor.

Sereact is the first production-ready Vision Language Action Model (VLAM). An AI brain for every robot, built to handle the chaotic reality of modern logistics.